What is skew rolling process?

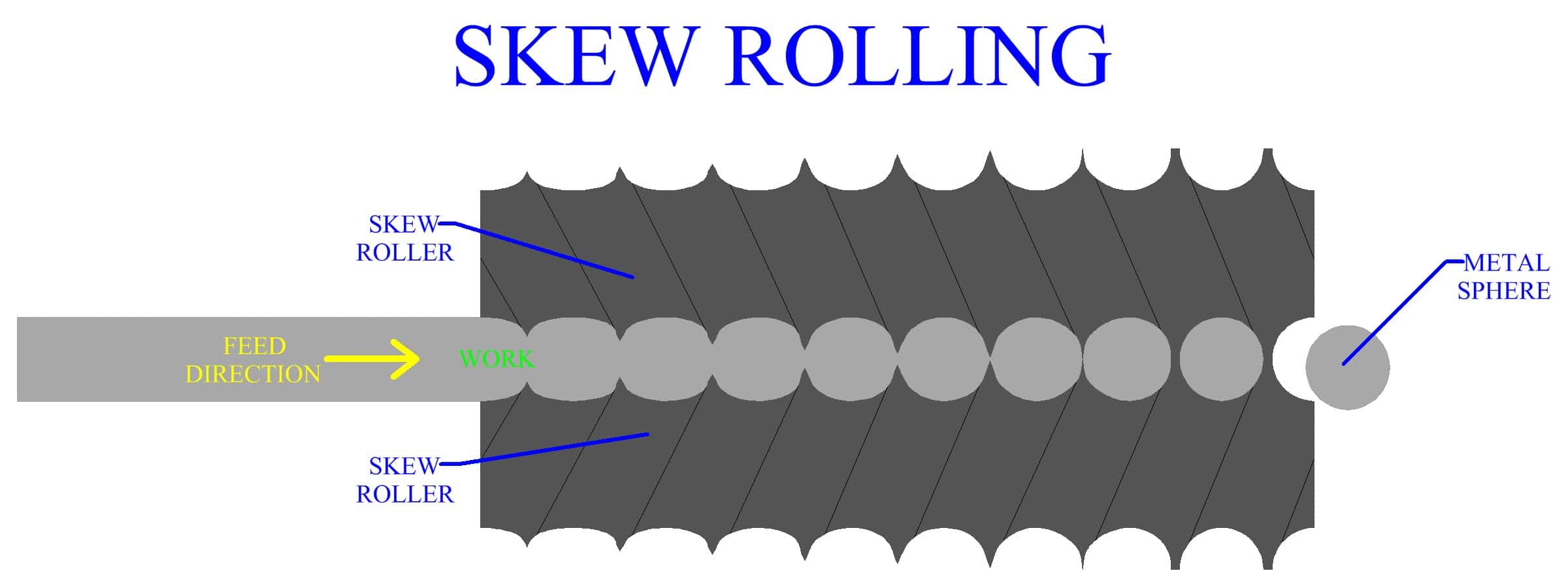

Skew rolling is a metalworking process used to form balls or cylindrical shapes from metal rods or billets. The process involves feeding a metal rod or billet through rotating rolls that have specially designed grooves. As the rolls rotate, they exert pressure on the metal, causing it to deform and flow into the grooves, forming the desired shape.

One of the unique features of skew rolling is the angle at which the rolls are positioned. The rolls are skewed at an angle relative to the direction of the metal flow, which helps to control the metal deformation and create a more uniform shape. The process can also be adjusted to produce various shapes and sizes, such as balls, cylinders, and cones.

Skew rolling is commonly used to produce steel balls for bearings, grinding media, and other industrial applications. The process offers several advantages over other methods of ball production, including:

- High production efficiency: Skew rolling can produce large quantities of balls quickly and efficiently, making it suitable for mass production.

- High precision: The process can produce balls with high precision and uniformity, resulting in better performance and reliability.

- Cost-effective: Skew rolling requires less energy and tooling compared to other methods of ball production, making it a cost-effective solution.

- Improved material properties: Skew-rolled balls have improved surface finish, hardness, and wear resistance, making them ideal for use in high-stress applications.

In conclusion, skew rolling is a versatile metalworking process that has found a wide range of applications in the industrial sector. Its ability to produce high precision, uniform shapes quickly and efficiently, makes it an attractive alternative to other methods of ball production.