skew rolling process and how it works?

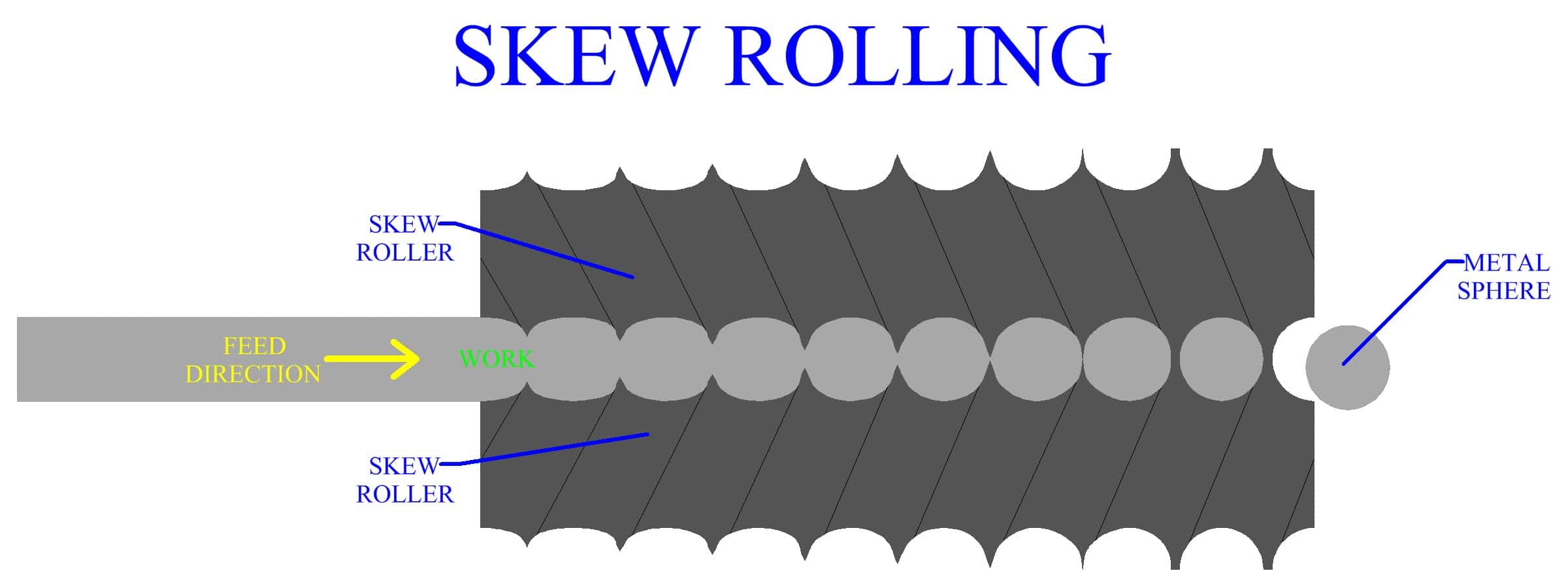

Skew rolling is a metal forming process that is typically used to produce steel balls. The process involves feeding a steel billet into a rolling machine, which then applies pressure and deforms the billet into a ball shape. Unlike traditional rolling processes that involve continuous rolling, skew rolling achieves the desired shape by rotating the billet at an angle relative to the direction of the rolls.

The rolls in a skew rolling machine have a special groove pattern on their surfaces, which helps to shape the metal into a ball. The groove pattern is often designed to produce specific types of balls, such as grinding media balls or bearing balls. The machine continues to roll the billet until it reaches the desired size and shape.

One of the key benefits of skew rolling is that it allows for the production of steel balls with a high degree of precision and consistency. The process can produce balls in a wide range of sizes and shapes, with tight tolerances and minimal variation in quality. This makes skew rolling ideal for use in industries such as mining, cement, and power generation, where reliable and high-quality steel balls are necessary for efficient operation.

Another advantage of skew rolling is that it is a highly efficient process that reduces waste and energy consumption. Because the process is automated and can be optimized for specific types of balls, it requires less energy and produces less waste than traditional rolling processes. This can lead to significant cost savings for manufacturers who use skew rolling to produce their steel balls.

Overall, skew rolling is a versatile and efficient metal forming process that offers a number of benefits over traditional rolling methods. Its ability to produce high-quality steel balls with a high degree of precision and consistency makes it an excellent choice for many industrial applications.