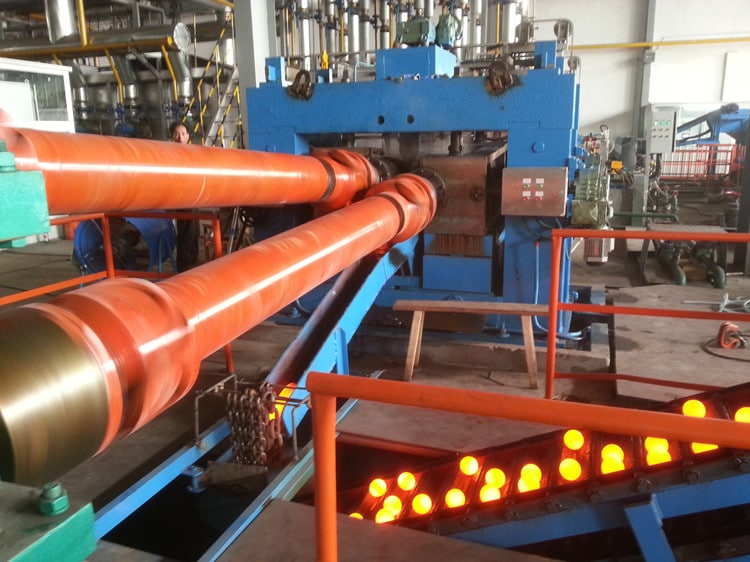

Improve the Fineness of the Mineral Aggregate in the Ball Mill Crushing Operations

Suchuang Machinery Equipment Co., Ltd(http://skewrollingmill.com)

Email: info@skewrollingmill.com

Grinding balls in the operation of crushing in Ball mill, the ore milling quality and fineness directly related to the purity of the mineral aggregate.

When the plant capacity with changes is in the grade of ore dressing, the great relationship with the nature of the ore and the means can improve concentrate grade. Beneficiation process is basically fixed, the ore has been ground to a certain size, and then rely on finely ground measures to improve the concentrate grade, the ability of the ball mill will inevitably decline. If it is in the continuous improvement, to improve quality improvement process based on the ability of the ball mill may not be reduced, and even improved to varying degrees.

Some individual concentrator while using a fine sieve is mainly by reducing the particle size of grinding to improve the quality of iron ore concentrate. However, due to the different nature of the ore, the ore grind ability different. Although in the same ball mill grind size, the useful minerals and gangue minerals monomer dissociation degree are not the same, but to make the most mineral monomer dissociation , which would inevitably mean that a small amount of the living body and over crushed minerals present in the grinding minerals, the impact on the improvement of quality of the concentrate. For high-grade concentrate, it is needed to take the approach to reduce the capacity of the mill to improve the grind size, and reduce the number of the living body the most useful minerals and gangue full dissociation. Concentrate grade finer grind size requirements over crushed phenomenon is more serious. The concentrate grade rises from 1976 65.13% in December to 66.35% in July 1977 to June 1978, and the amount of ball mill processing down to 53.40t 62.48t / (units / h) / (units / h), a decrease of 9.08t / (units / h).